Retrieval of radioactive waste from storage chamber 7/725

BGE (Bundesgesellschaft für Endlagerung mbH)

UNS - Uniper Nuclear Services GmbH

EP - Ercosplan Ingenieurgesellschaft Geotechnik und Bergbau mbH

TIS - TÜV Rheinland Industrie Service GmbH

INGE ZPP - ZPP Ingenieure AG & BUNG-PEB Tunnelbau-Ingenieure GmbH

Remlingen, Germany

Concept planning 2015 to 2020

Draft planning 2021 until presumably 2025

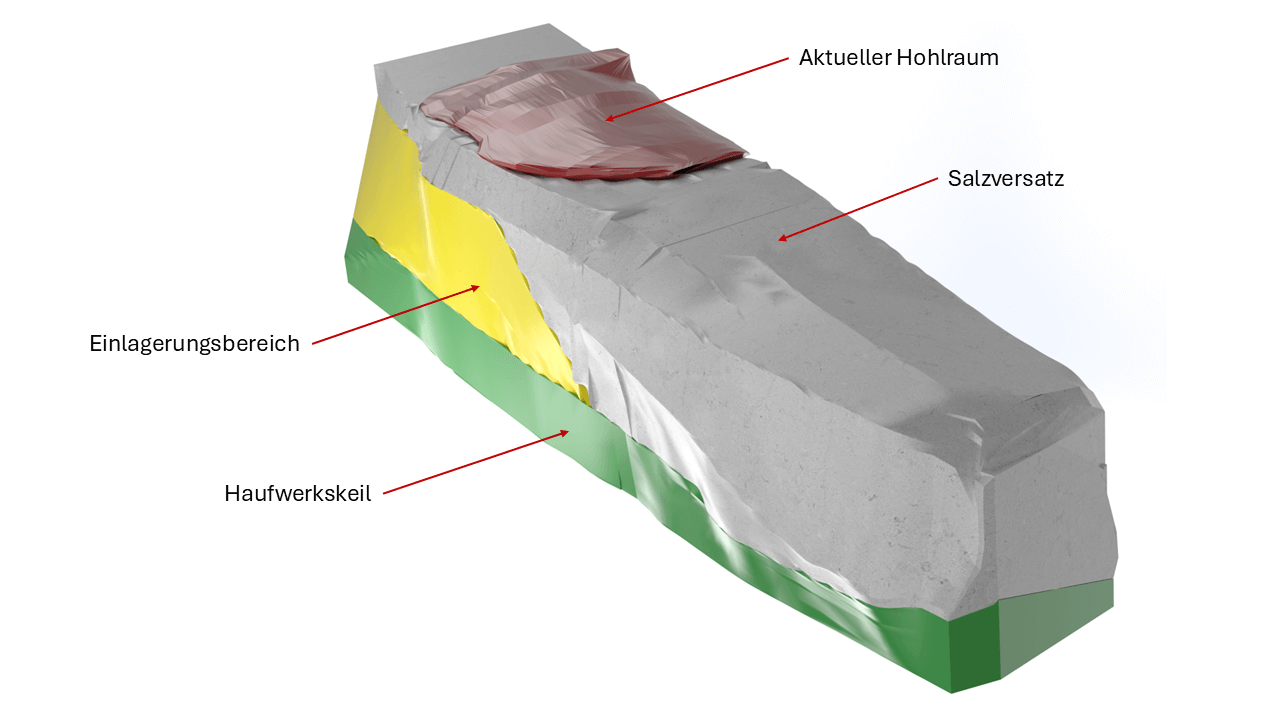

Between 1967 and 1978, around 47,000 cubic meters of low- and intermediate-level radioactive waste were stored in the former ASSE rock salt mine, which is located near Remlingen near Braunschweig. This waste, which is packed in a total of 124,486 containers, was stored in 13 former open salt mining chambers. Two of these emplacement chambers (ELK) are located in the central part of the mine and are known as the "Central Chamber Group". ELK 7/725 also belongs to the central chamber group, but is located slightly higher and separately from the storage chambers on the main storage level at a depth of 750 m on the 725 m level.

In order to retrieve the radioactive waste and the salt dumped during the emplacement process from the ELK 7/725 and package it safely in terms of radiation protection, REDPATH DEILMANN is developing a concept with remote-controlled retrieval technology in collaboration with three other partners from the nuclear and mining sectors.

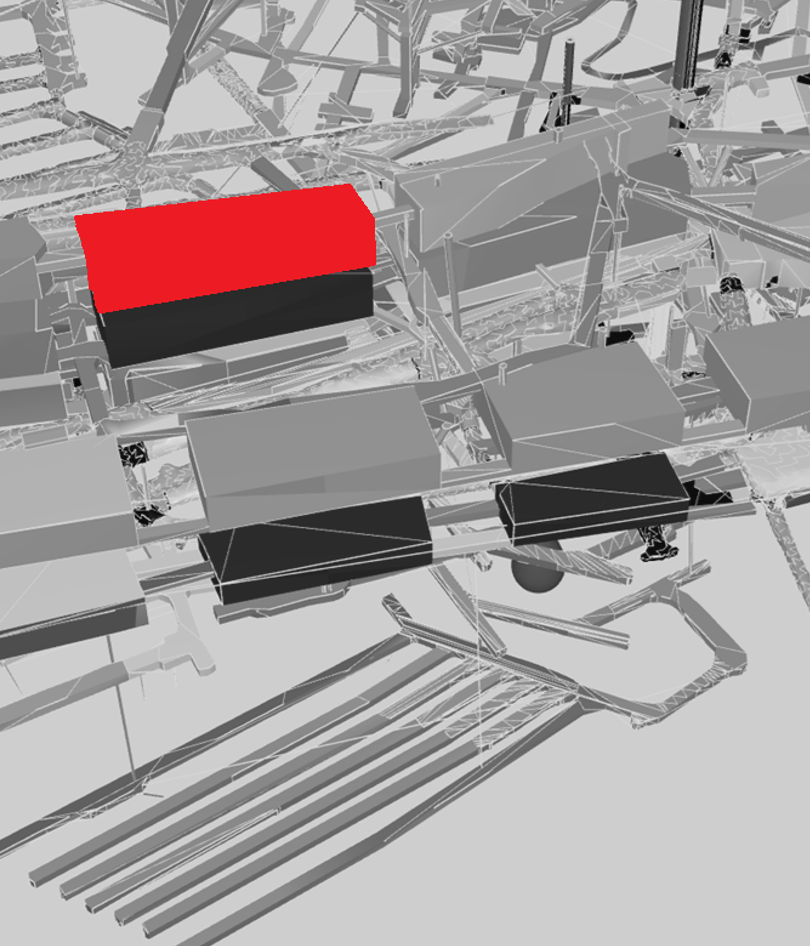

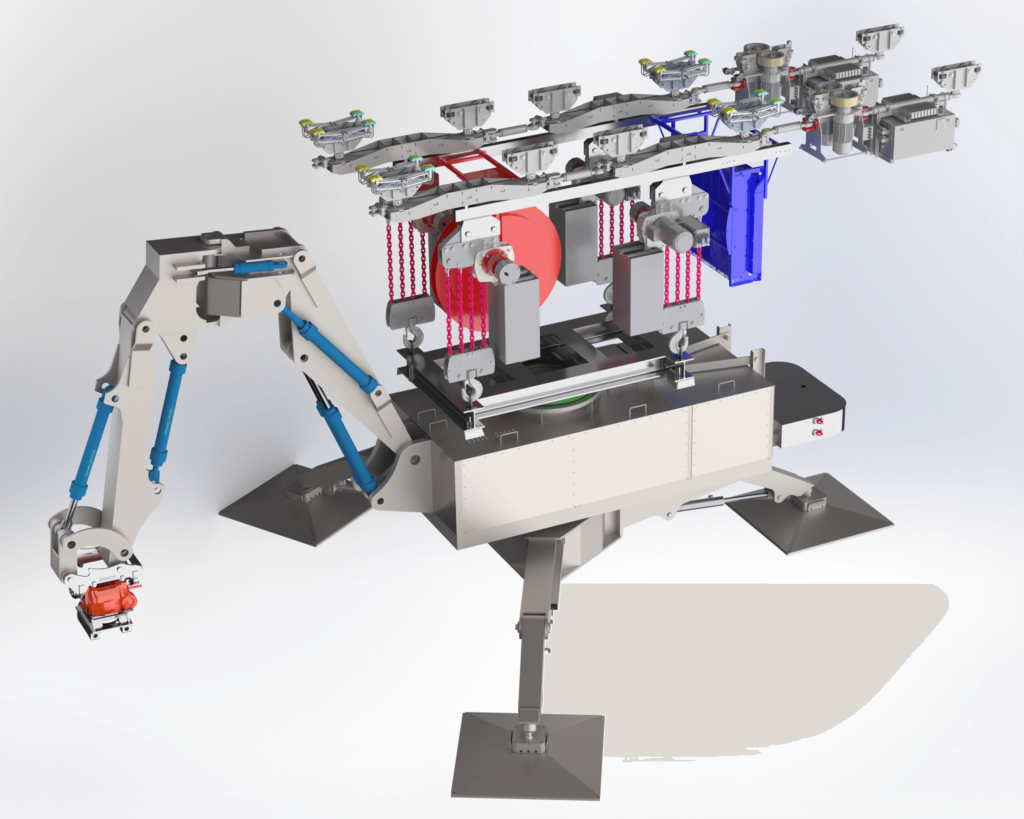

The tripod, a kind of remote-controlled excavator on a three-legged frame, which is moved and secured via a monorail overhead conveyor, is the cornerstone for retrieving the radioactive waste from the ELK 7/725.

The so-called "tripod", a type of excavator on a three-legged frame, will carefully uncover the radioactive containers dumped in ELK 7/725 and load both the containers and the resulting salt pile into specially designed transport containers. These are then placed in outer packaging in an underground packaging station and then transported safely to the surface via the Asse 5 shaft , which has yet to be constructed. Thanks to the self-levelling three-legged frame, the tripod can also work on the partially uneven ground above the radioactive waste within the ELK 7/725 without tipping over. In the event that the subsoil should give way to a greater extent, the tripod and all other retrieval equipment within the ELK 7/725 are suspended from a standard mining monorail. This allows the entire retrieval equipment to be moved in the ELK 7/725 and is additionally secured.

The working group from the concept planning, reinforced by a partner from the tunnel sector, is currently working on the design planning for the retrieval of the radioactive waste from ELK 7/725. In this planning phase, there are many areas that need to be planned in detail. Among other things, the geological conditions must be taken into account and evaluated, the entire retrieval technology and the lock areas must be designed and many consultations with the client (BGE) and authorities must be carried out. In addition, the infrastructure surrounding the retrieval, including ventilation, must be planned.

As already defined in the concept planning, this takes place in the three phases of retrieval listed below.

Phase A: Preparation

Phase B: Retrieval of the radioactive waste

Phase C: Follow-up