With over 135 years of experience in the shaft and mining industry, we are able to combine proven methods with state-of-the-art technology. During the execution phase, we ensure that the construction period is kept as short as possible without compromising functionality and trouble-free operation in the future. Strict quality controls allow us to minimize the risk of downtime during the operational life of the shaft system.

Our core competence lies in the construction of all types of mine workings, vertical, inclined and horizontal. We offer customized solutions for every requirement - development of new deposits, the expansion of existing mines with new opencast or blind shafts or the deepening of existing shafts. The geological, technical, climatic and ecological conditions require different methods.

We offer you all sinking methods, including full face sinking and sinking on a pilot hole with an existing undercut. Do you already have a mine but no undercut to the new shaft starting point? No problem! In addition to drilling the pilot hole with our parent company in Canada, we are also happy to provide you with the undercutting.

The conventional sinking method using drilling and blasting is particularly impressive due to its high degree of flexibility. It enables a fast and effective response to changing boundary conditions and unforeseen circumstances. This means that the sinking process can be carried out safely and on schedule.

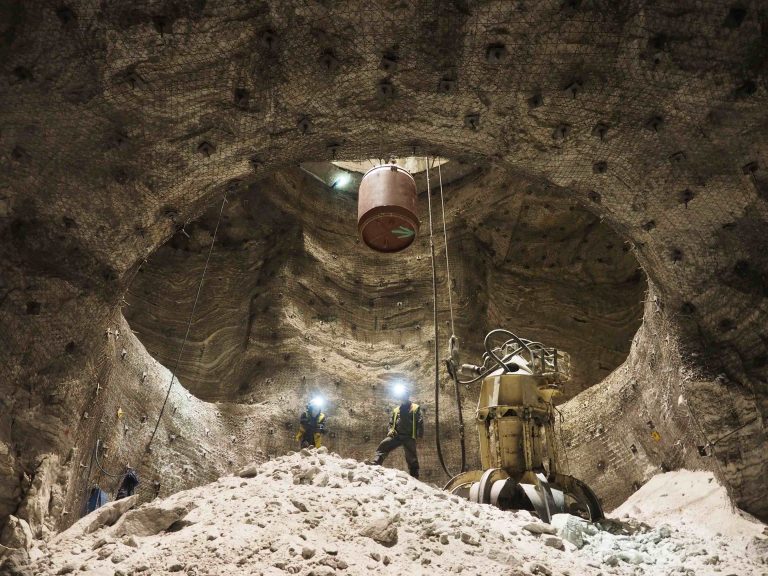

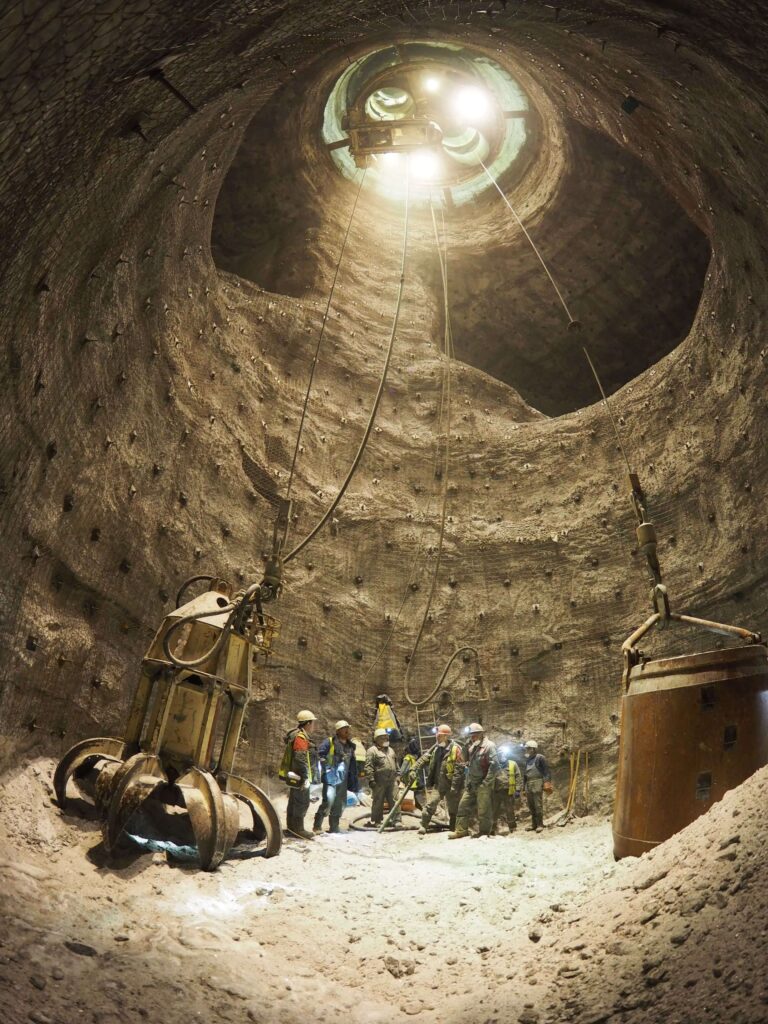

The conventional sinking method is a cyclical process in which the individual phases of "drilling the blast holes", "blasting", "loading the muck" and "inserting the support" are repeated cyclically.

After blasting, the debris was loaded into a bucket with a grab for decades. To increase efficiency and safety in the loading process, REDPATH DEILMANN is increasingly focusing on innovative solutions.

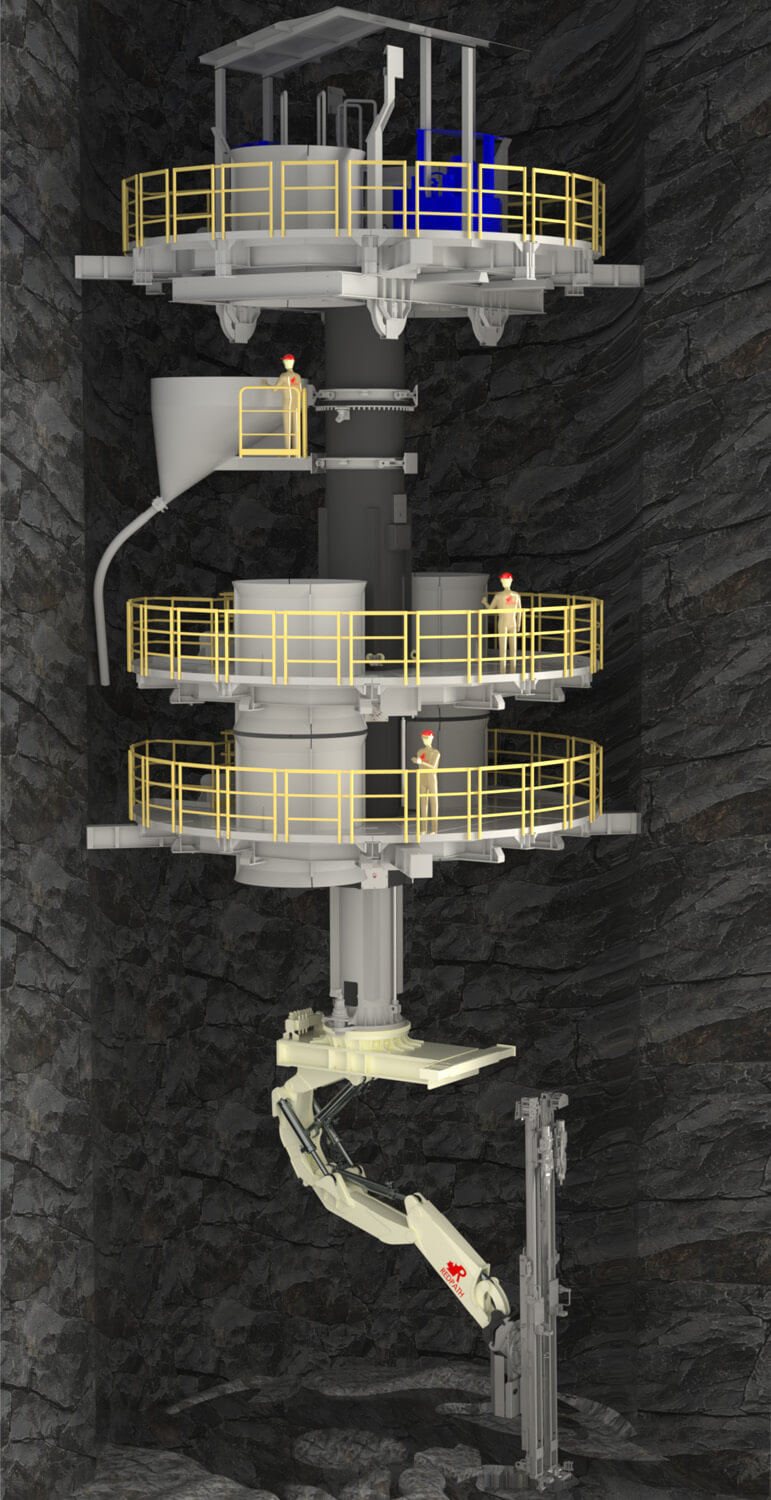

The RD S100 shaft excavator is one of these innovations that retains the advantages of the conventional sinking while integrating automation technology.

In contrast to the conventional grab, the S100 not only represents a new loading technology for loading the pile into the bucket, but also offers further advantages:

These features enable an increase in performance of 25% as well as an increase in work safety, as unmanned work can be carried out on the bottom of the shaft.

The shaft excavator impresses with its wide range of applications. In addition to classic loading work, the excavator can also be used to speed up the following work processes:

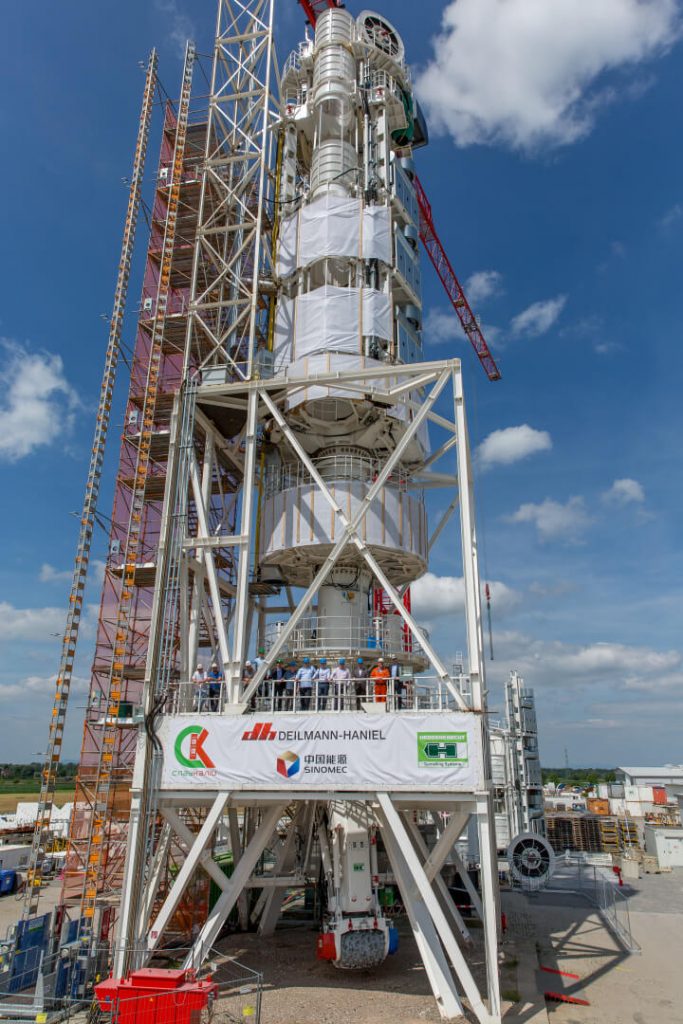

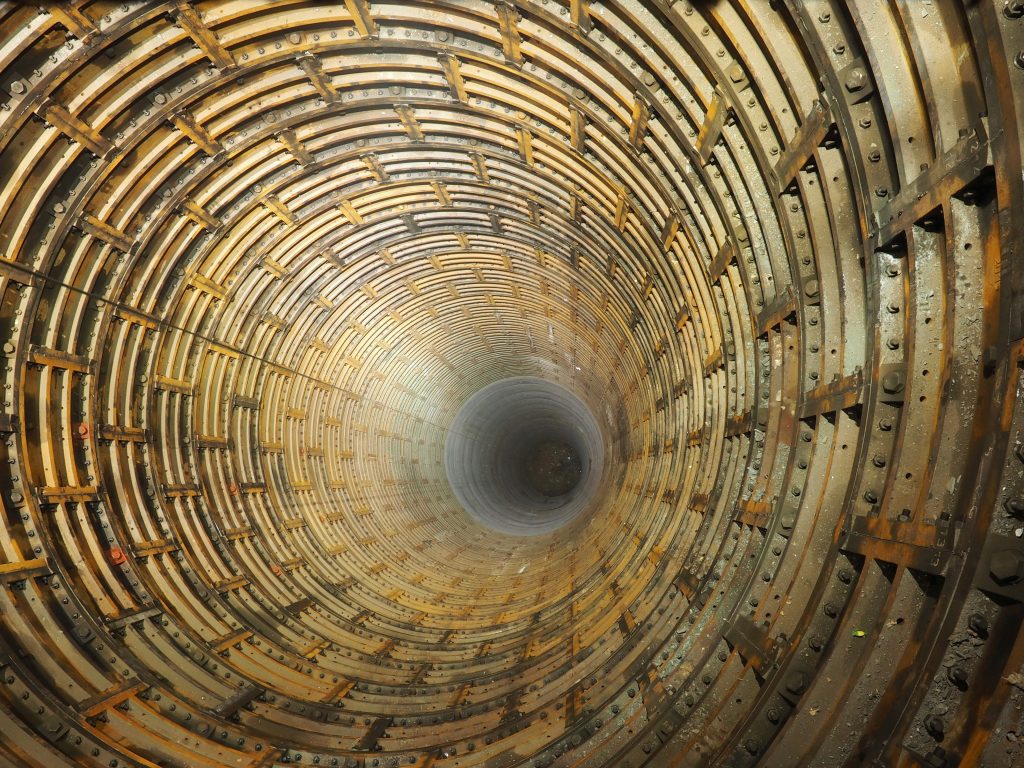

In contrast to conventional sinking methods, mechanical sinking is not carried out by drilling and blasting, but by cutting or peeling with a shaft boring machine. REDPATH DEILMANN has particular expertise in the use of shaft boring machines of the type SBR (Shaft Boring Roadheader) from Herrenknecht. A rotating, swiveling and telescoping roadheader boom with milling drum mounted on the lower deck of the SBR cuts the sinking base into approximately 200 mm thick slices. The cut material is sucked in at the cutting head using a pneumatic mucking system (PNM) and either stored temporarily in a bunker in the central machine body or unloaded directly into the buckets for transportation to the surface.

A major advantage of mechanized sinking is that the cutting chamber (the sinking floor) is not manned by personnel during normal operation. This means that the shaft lining can be installed in parallel with the excavation without compromising work safety. The parallelization of the work steps in combination with the high rate of advance of the shaft boring machine enables high sinking speeds. However, shaft boring machines place increased demands on the geology and sometimes require considerable set-up times, so that their economic use must be examined in detail.

We are happy to support you in your decision-making process!

For projects with challenging geology, such as unstable rock or water-bearing horizons, it is possible to combine the two sinking methods with the two following methods for rock stabilization and sealing to create a special method for sinking shafts.

In the freezing process freeze holes are drilled from above ground on a circle outside the excavation diameter, into which freeze pipes are then installed. A refrigerant is circulated through the freeze pipes at temperatures as low as -36°C, freezing the surrounding rock and creating a watertight and load-bearing frost cylinder. The shaft is sunk under the protection of this frost body and lined with a watertight lining system.

This process was developed around 1883 by the German engineer Friedrich Hermann Poetsch and has been used successfully worldwide ever since. REDPATH DEILMANN has gained extensive experience in the construction of over 200 freeze shafts.

In the injection process, cone-shaped drill screens are created from the bottom of the shaft, into which cement suspensions or synthetic resins are then injected in sections. The result is a sealing ring around the shaft, which greatly reduces the inflow of water during shaft sinking and increases the stability of fissured rock. The processes of sinking, creating and grouting the drilling umbrella are repeated alternately, with the drilling and grouting umbrellas overlapping.

This shaft area is then permanently secured with a lining of watertight steel casing and reinforced concrete or cast-iron segments.

Soil freezing is one of our core competencies in shaft, civil engineering and tunnel construction. This environmentally friendly process effectively secures and seals water-bearing soils and loose soils.

Existing shafts are up to 100 years old and are exposed to a variety of loads. Despite durable construction methods, they are subject to natural wear and tear. We know the typical damage patterns and offer customized solutions for renovation, conversion and extension.

We are your partner for shaft construction and mine maintenance - from refurbishment and backfilling to rope replacement. We also plan and install shaft pipelines, secure and rehabilitate routes and develop efficient solutions.

Taking all relevant factors into account, we prepare feasibility studies and analyses and derive well-founded time and cost estimates. From approval to execution, we guarantee efficient planning in accordance with applicable standards in Germany and abroad. We ensure sustainable solutions through innovation and development.

#bettertogether